Draft Version 1.0 – 1Jan 2013

This class is based on the principals of close, fair and low cost racing. This will make it both an ideal entry level class for the driver who wishes to try his or her hand at RC racing for the first time, but the rules for the class will also cater for the more competent driver who wishes to take their racing further. In the interests of keeping racing costs reasonable, price limits have been placed on certain items and there is strict guidance as to the use of additional upgrade parts and components. This should also ensure that the performance of each car is more dependent on driver ability and good setup than on budget. The Rules outlined below are based on the BRCA GT12 Rules but amended to accommodate the Mardave V12 Mini, as well as the Schumacher GT12. In order to minimise costs, the GERCC club standard will be the 21.5T Brushless motor linked to a ‘Zero Timing ‘Electronic Speed Controller (ERC) and a 7.4 volt battery. These are defined in more detail below.

Construction Rules.Wheels and tyres.

Wheel rim diameter maximum is 40mm. The tyres must be black except for side wall detail. Tyre treatments are permitted in accordance with GERCC rules and BRCA approved additives. Tyres must have a minimum width of 20mm and a maximum width of 26mm. Wheel nuts and/or axles must not protrude more than 2.0mm beyond wheels. No more than 1.5mm of wheel outer side may be exposed (not covered with rubber) on the outer edge of wheels.

Bodies, wings and bumpers.

Bumpers may be fitted but must be designed to minimise injury that could result from being hit by a car, also to reduce the risk of damage to other cars. Rigid bumpers made from non-resilient materials such as metal are not allowed. Other sheet materials should have an edge radius not less than 1.5mm. Only one wing is allowed on the car, maximum dimensions to be, width 165mm, chord 50mm, unless the original had more than one wing. The second wing must be to scale within 10% in size and location. Overall maximum width of the rolling chassis to be 165mm. All cars must have transparent windscreens, unless the actual car did not have transparent windscreens. Side and/or rear windows, if any, must be clear. All cars to have clearly visible identifying numbers to the Race Directors satisfaction. No portion of the chassis, wheels and tyres or any equipment may extend beyond the body, except aerial masts and four posts for the purpose of mounting the bodyshell. Roll-over masts/antennas must not be fitted. Only one drive motor is allowed per car. The recommended minimum ground clearance of the car, not including the spur gear, is 5mm; minimum 3mm under the spur gear. The use of countersunk holes and screws on the underside of the chassis is mandatory.

Definition of a Brushed motor.

Motors allowed – any 24Turn or higher brushed motor is allowed.

Definition of Brushless Motor.

13.5 brushless - Any motor listed in any of the Electric Board Homologation List for Brushless Spec Motors (13.5) as updated from time to time. 21.5 Brushless - Any motors listed in Appendix 3 to these Rules.

Definition of a Zero-timing Speed Controller.

Speed controllers may not be equipped with any form of automatic or programmable timing advance. If this feature is available on the particular speed controller it must be disabled and placed in an approved mode - i.e. the "ROAR blinking LEDs mode." Brushless Speed Controllers built without automatic or programmable timing advance will be allowed. The BRCA 12th Committee will provide a list of eligible speed controllers. Details of the requirement for the approved mode are contained in Appendix 2 – Zero-Timing Brushless Speed Controllers – and this requirement must be met for a speed controller to be eligible for racing in relevant GT12 Classes. When using a sensorless speed controller/brushless motor combination Rule 4.1 does not apply. Brushed Speed controllers are without restriction providing that they include an operating reverse function and are available with a recommended retail price not exceeding £65.

Batteries Allowed.

Any cells conforming to the current Electric Board battery list. All cells used in any competitions MUST be hard-cased unless the soft cased cells are caged within the chassis of the vehicle. Cars with 13.5 Brushless Motors will be powered by cell/s with a maximum nominal voltage of 3.7v. Cars with Brushed motors will be powered by cell/s with a maximum nominal voltage of 4.8v. Cars with 21.5 Brushless motors will be powered by cell/s with a maximum nominal voltage of 7.4v.

Chassis and Components.

The chassis component will consist of one continuous sheet of metal or glass- or carbon-fibre-reinforced plastic (composite) that extends from a minimum 10mm ahead of the front axle line and runs continuously along the car to end 25mm minimum behind the rear axle line. The chassis may not include any features designed to allow the front and rear axle to rotate along the central axis of the car relative to each other. (Intent – that the chassis supports all the suspension components and is sufficiently rigid not to be used as a working part of the suspension system/s). The material of the chassis component must be available from the manufacturer in a kit available at or below the price limit in Rule 6.7 (Intent – that the material used for the chassis must be included as the chassis in a rolling chassis kit, not solely as upgrades to a rolling chassis kit). Metal materials used in the rolling chassis may only be steel or aluminium. Special metals (such as titanium) are not allowed. Brass and lead only may be used as identifiable weights to meet the weight limit and when removed do not have any effect on the car’s function as a rolling chassis. (Intent – that special metals are not to be used as parts of the rolling chassis and its operation, either supplied as manufacturer’s original parts, add-on parts from any manufacturer or other supplier or made independently by the driver.) All suspension systems must operate independently of the chassis component. Separate dampers are only allowed on the rear suspension. Dampers requiring seals to prevent the egress of oil are not allowed. (Intent – that dampers are non-sealed ‘straw’ or ‘tube’ style. Dampers with oil contained in a sealed reservoir are not permitted). Front suspension may be independent provided that the suspension design does not have any pivot, rod or other mechanism that alters the wheel camber in roll relative to the chassis during its full travel. (Intent – that suspension systems from Touring Cars, GT10 cars, 12th cars and F1 cars featuring pivoting suspension arms are not used). The rear axle must be a solid straight axle and may be fitted with an integral differential. Only a single fixed speed transmission is allowed. Gears in the single fixed speed transmission must be 32DP or 48DP only. Rolling chassis kits for the GT12 class may not have a recommended retail price higher than £99.95. A rolling chassis kit may exclude all electrics and bodyshell, but must include one complete set of wheels and tyres suitable for use on a carpet racing surface. Rolling element (ball) bearings are allowed on the front and rear axles. Cars may only have two driven wheels with the drive to the rear axle.

End of Construction rules.

The following Appendices form part of the Rules above.

Appendix 1 - Bodyshells – (Construction) Rule 1.23.

Only GT and saloon body shells are allowed. Principally these are realistic representations of road-going cars including those used as the basis for cars entered in FIA GT and Saloon racing competitions. All shells must be a reasonable representation of the full sized car. Bodyshell when painted will usually have the headlights, front grill and rear lights picked out in a detail that clearly separates them from the other body colours. (Intent – that bodies painted all one colour are discouraged, and paint schemes that reflect a reasonable representation of a full-size GT racing or touring car are preferred.)

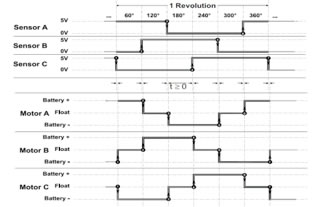

Appendix 2 – ‘Zero timing’ brushless speed controllers – (Construction) Rule 4.

‘Zero timing’ brushless speed controllers. A speed controller that has a 'zero timing profile', that does not alter the fixed position pre-set mechanical timing of the motor in any way and disables any advanced motor control; functions (i.e. Boost, Cheat mode, Turbo etc.). This profile is known as ' Boost 0'.

The commutation sequence is limited to "6-step" type and commutation of the Speed control must follow the motors hall sensor signals 1:1. Therefore no change of timing (either advance or retard) is allowed at any RPM. When the "Boost 0" profile is activated, it will be identified by a blinking LED or LEDs while the ESC is armed and in neutral position. The Section reserves the right to retain a speed controller and motor after the conclusion of a meeting to measure its performance against the above criteria in a controlled environment. The equipment, or identical new replacements, will be returned to the competitor within 5 working days. Sanctions may be taken against a competitor and/or manufacturer if a controller is found to be non-compliant.

Appendix Three – 21.5 motors allowed – (Construction) Rule 3.2

21.5t motors which have locked or fixed mechanical timing (ideally from the EB list) are suggested. For example: HobbyWing / Xerun “Stock” 2.15t (part number 90040150/1) SpeedPassion Ultra Sportsman V2 21.5t (Part Number SPF21V2) SpeedPassion Ultra Sportsman V3 21.5t (Part Number SP00008) Novak SS Pro 21.5t (Part Number 3421) Losi Xcelron 21.5t (Part Number LOSB9409) The Corally Pro Red motor and the LRP X12 motor are specifically excluded. If a model is chosen that does have a degree of mechanically adjustable timing it is up to the driver to prove that the timing is set to zero degrees. (Intent – that the 21.5 motors are not used with mechanical timing advanced as this will give a performance advantage over the 13.5/1S combinations. It is intended that use of 2S cells simplifies installation, not gives a performance advantage.)

End of Appendices